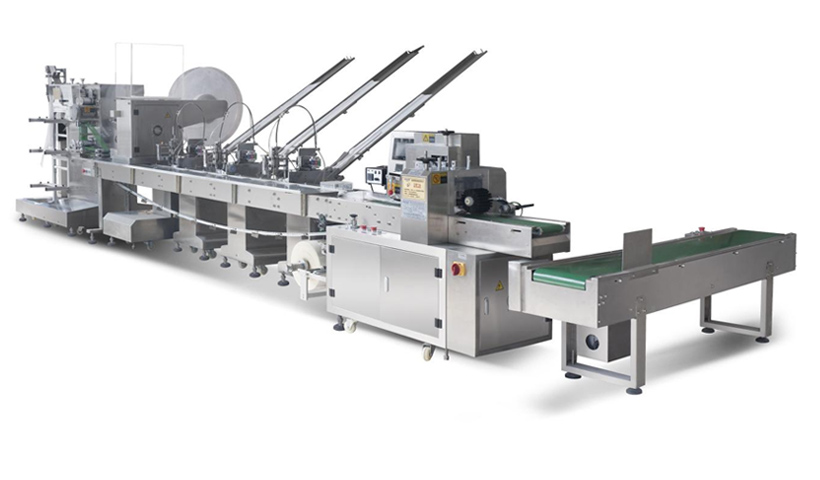

This device uses a color touch screen for control, and its main control circuit employs a high-speed intelligent chip which ensures accurate measurement, automatic detection of electrical failures, and easy operation and adjustment. It has an automatic memory function to avoid repeated adjustments in packaging products of the same specifications. The device adopts a high-quality dual-frequency conversion and simple mechanical structure, which is easy to maintain, less prone to wear and has a long service life.

Why Choose Wooden Cutlery

Production Equipment From SAE

Auto Full-Process Wooden Cutlery Machine Manufacturer

Advantages Of SAE Wooden Cutlery Equipment Manufacturer

Constant pursuit, only to serve you better

One-stop equipment procurement solution provider

SAE provides full-process equipment for the production and processing of wooden disposable tableware, including log production line, molding production line, packaging production line, etc., to meet the needs of building a factory from zero.

Strong professional technical guidance

Whether building a factory from zero or upgrading equipment, SAE has professional engineers to provide customers with professional and reasonable technical guidance to help customers solve technical problems.

Professional after-sales management team

During the use of the equipment, if there are technical problems, you can consult SAE at any time. Our after-sales engineers will respond quickly and provide solutions to customers so as not to delay the production schedule.

Experienced Shipping Department

SAE has a professional logistics operation department, and there are special personnel in charge from the packaging and shipping of the equipment to the customs declaration and export to ensure that the equipment is safely shipped and the relevant documents are complete.

Provide Equipment For Each Steps Of Wooden Cutlery Manufacturing

Complete Solutions For Wooden Cutlery Production Lines

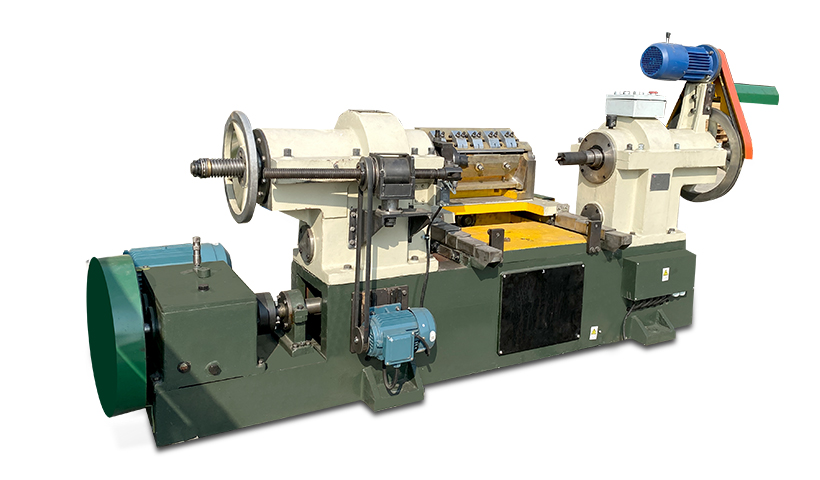

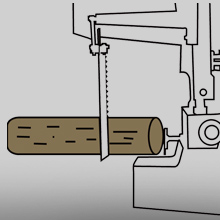

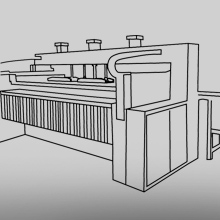

Vertical Saw Machine

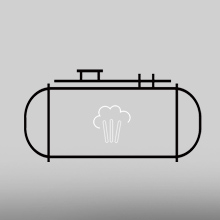

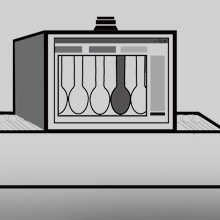

Lndustrial Drying Ovens

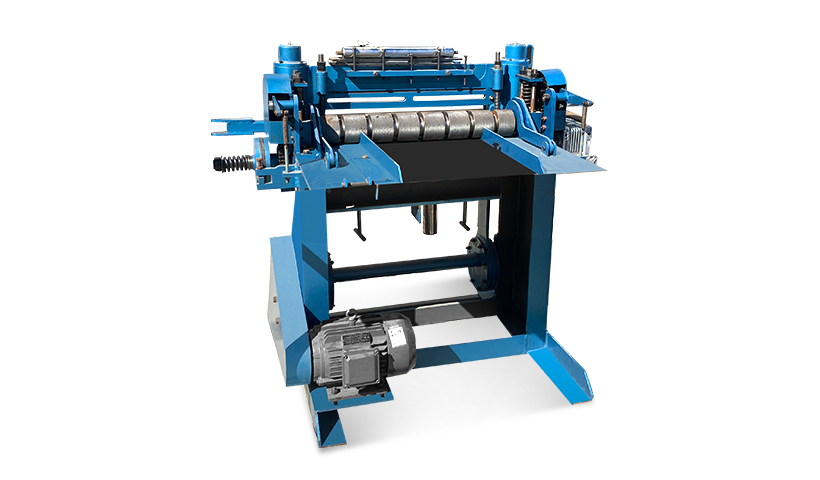

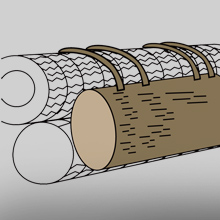

Veneer Peeling Machine

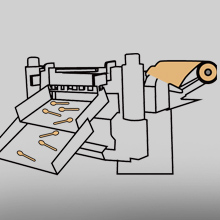

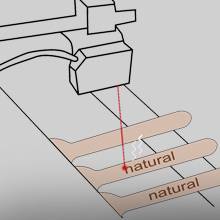

Die Cutting Machine

Industrial Drying Ovens

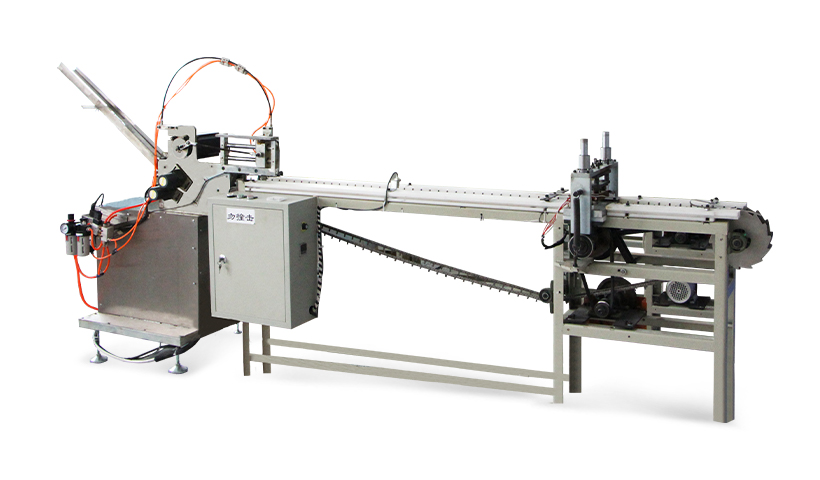

Wooden Cutlery Making Machine

Vision Inspection Cameras

Hot Stamping Machine

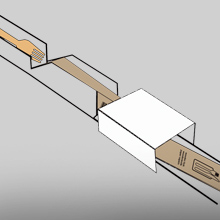

Automatic Packing Machine

- Fast Quote

- Fast Delivery

- 3 Years Warranty

- Complete Solution

- Tel

- *Title

- *Content